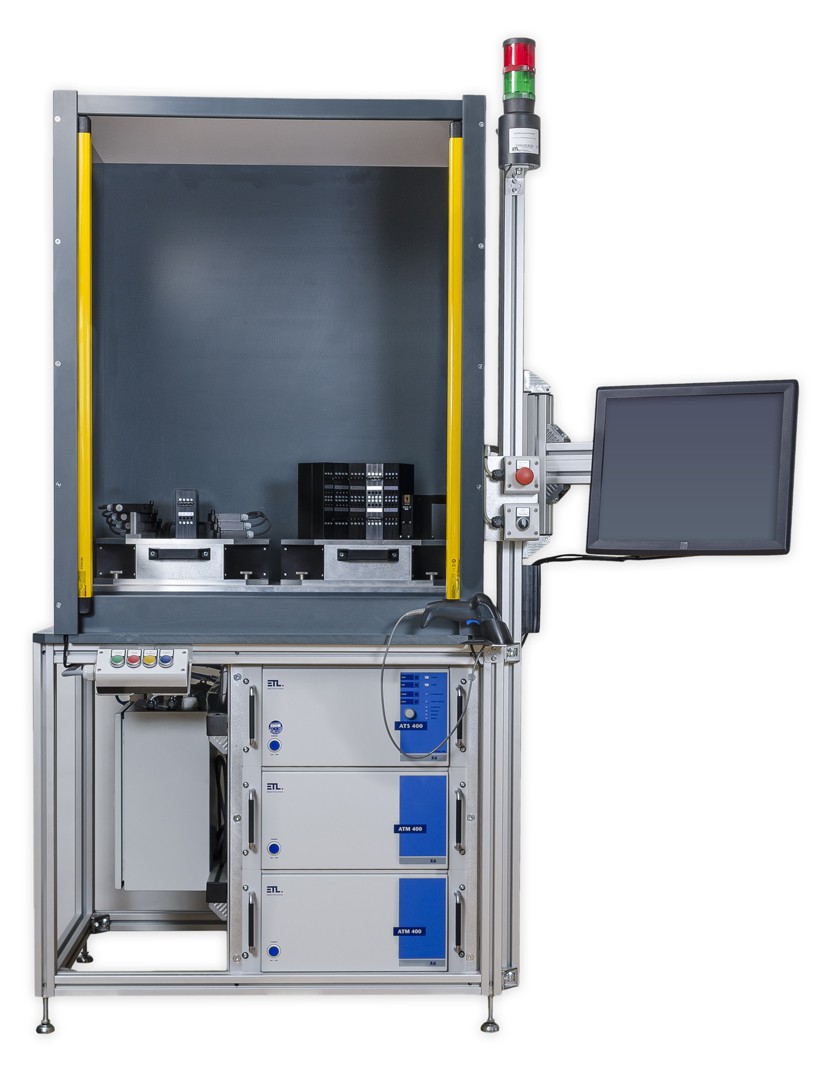

Automatic Test System - Model LG-L

0.5 - 25 A AC, 1 - 500 mΩ @ @

Insulation resistance @ @@ 50 - 1 000 V DC,0.5 - 400 MΩ,@ @ @ @ @ @ @ @ @ @ @ @ @ @ @ @ @ @ @@ current-limited, EN 50191 @ @

Function test, mains @ @ @ 230 V AC, dep. on mains supply@@ @ @ @ @ @ @ @ @ @ @ @ @ @ @ @ @ @ @@ 0.01 - 10,00 A AC @ @

Continuity test @ @ @ @ @ @ @@ 0.5 - 25 V AC, 1 - 600 Ω @ @

General data

| Input voltage | 230 V, 50 Hz / 60 Hz |

| Mains connection | IEC mains cable supplied |

| Tolerance mains voltage | +/- 10 % |

| Current consumption | max. 10 A |

| Fuse | 10 A, T, 5 x 20 mm, 250 V |

| Displays | X2-Variation: no display, remote control variation |

| Operating system user interface | X2-Variation: Only remote control variation X4-Variation: WIN CE ® X5-Variation: WIN CE ® X6-Variation: WINDOWS ® X8-Variation: WINDOWS ® |

| Storage of test plans and results | X2-Variation:Storage through superordinate control unit X4-Variation:Selectable local on SD-CARD, optional USB or LAN X5-Variation:Selectable local on SD-CARD, USB or LAN X6-Variation:Selectable local on hard disk, USB or LAN X8-Variation:Selectable local on hard disk, USB or LAN |

| Setting of test parameters | Manual in the single test menu or via test plan (user interface DataView) all-automatic via interface (ASCII, DLL, LabVIEW, .NET) |

| Error message | Audio, optical and via interface |

| Dimensions (W x H x D) | 400 x 210 x 420 mm |

| Weight | Approx. 23.8 kg |

| Casing | Metallic case, RAL 7035 |

| Basic equipment with delivery | Manual, mains cable, safety circuit plug |

| Calibration | Factory-calibration incl. calibration certificate DAkkS-calibration (BS/EN17025 similar to UKAS) option |

Environmental conditions

| Casing | IP20 |

| Humidity | max. 80 %, not condensing |

| Allowed range of temperature | + 5 to + 40 °C |

| Max. hight above sea level | 2 000 m |

| Cooling | Internal fan cooling |

Interfaces

| ETL-Interface / Digital-IO | Start, stop, good result, bad result and test in progress (all digital outputs are solid state) |

| RS232 / PC- Interface | Remote control interface for customer applications or for data management package ETL DataView |

CAN Interface | For expanding the test system by additional devices and additional ext. extension test modules |

| LAN Interface | For connection to the customer's own network, e.g. for storage of the test results, depending on the operating variation |

| USB port | For connection to external storage device as well as keyboard and mouse, depending on the operating variation |

| VGA-port | For connection to an external display, only X6- and X8- models |

Connections – test object, safety components

| Signal lights | For connecting a combined green/red warning light according to EN 50191 |

| Safety circuit | Three different options of safety circuit available |

| Connections for the test object | L1/HV1: connection phase DUT * |

| Mains connection | IEC connector, 10 A, with fuse |

| USER-Interface / Digital-IO, optional | Digital interface for full remote control (all digital outputs are solid state) |

| Analogue-IO, optional | 4 analogue input signals (0 - 10 V DC) 2 analogue outputs (D/A), for example: results monitoring |

| Frequency-IO, optional | 4 frequency inputs for recording speed- and there rotation-direction |

Expanded device-Setup

| User administration | Individual setup password protected |

| Signal configuration | Individual setup for digital results |

| Data manager for test plans and results | Individual setup of storage options, storage location, naming of the result files and automatic creation of sub-directories |

| Buzzer-options | Individual setup of acoustic warning |

| Basic settings of the test system | Language selection, device name, interface configuration |

| Start of the operating interfaces | Individual setting of the start menu. (e.g. direct start in the test selection menu via barcode) |

| Test selection menu | Manual via selection window, process reliability via barcode- or keyboard entry, via digital interface or through read-out of a files |

| Manager for dummy testing | Dummy testing can be set according to the configuration: automatically requested (e.g. at program start, at user changes, via digital interface, after a certain number of test objects, a certain time or after a time interval) |

| Locking options for the test cage | Individual setting of the locking options (during the test, on Good, on Bad, …) Optional module |

Start options for testing

| Start- and stop- signal by test pistol * | Special 4-wire-technology for automated test start and connection monitoring. Test voltage will only start when both test pistols have contact to the test object. (depending on the built-in test modules) |

| Automatic start via safety circuit | The test can be started when the cage door is closed, for example. |

| Start button on the device | Front panel button for test-start |

| Start via contact monitoring, patented* | Start will only take place if the source and sense are connected, without cable break |

| Start by serial interface | Start takes place through higher-level control system (SPS or PC) |

| Start by digital interface | Digital I/O for example as PLC, footswitch, push button, etc. … |

| Start options | individual setup of start modes |

(*) patented:

The ETL contact monitoring (KÜ) is a patented technology:

German patents: 100 11 466.0 and 100 11 345.1

European patents: 01 105 568.8 und 01 105 567.0

Electrical safety and norms

| EN 61010-1 | safety regulations for electrical measurement, control- and lab- equipment |

| EN 61326-1 | electrical measurement, control- and lab- equipment – EMC-requirements |

| EN 61000-3-3 / EN 61000-3-2 | Electromagnetic compatibility (EMC) |

| EN 50191 | Erection and operation of electrical test equipment |

| EN 60598-1 | luminaire / Part 1: General requirements and tests |

| Contamination level | 2 |

| Protection class | 1 |